Chain Tensile Testing Using Electromechanical Universal Testing Machines

Chain Tensile Testing Using Electromechanical Universal Testing Machines

This case study demonstrates the systematic approach to conducting chain tensile tests using electromechanical Universal Testing Machines (UTM), providing valuable insights for manufacturers and engineers in the power transmission industry. Chain tensile testing is a critical quality control procedure that ensures chains meet or exceed specified strength requirements, providing essential data for safety factor calculations and application suitability assessments.

Theoretical Background

Chain tensile testing involves applying controlled tensile forces to chain specimens until failure occurs, providing critical mechanical property data including ultimate tensile strength, elongation characteristics, and failure modes. The test serves as a destructive evaluation method that determines whether chains can withstand specified loads in their intended applications.

The importance of tensile testing extends beyond simple quality control. For roller chains operating on continuous drives, the rule of thumb requires that chain loads not exceed 1/6 to 1/9 of the chain’s tensile strength, depending on master link configurations. This safety factor ensures adequate service life and prevents premature failure through linkplate fatigue.

Electromechanical UTM System Specifications

Machine Configuration and Capabilities

Modern electromechanical UTMs provide exceptional precision and control for chain testing applications. The test system utilized in this case study featured a 50 kN capacity frame with Class 1 load cell accuracy per ISO 7500-1, ensuring measurements within ±0.5% of reading throughout the test range.

The electromechanical drive system offers several advantages over hydraulic alternatives for chain testing. Precise crosshead speed control from 0.01 to 1000 mm/min enables compliance with various standard requirements, while the servo motor and ball screw configuration provides exceptional repeatability. Advanced data acquisition systems sample at 1000 Hz, capturing detailed force-extension relationships crucial for proper analysis.

Specialized Chain Gripping Systems

Chain tensile testing requires specialized gripping fixtures that accommodate the unique geometry and loading characteristics of chain links. Proper grip design prevents stress concentrations and grip-induced failures while ensuring uniform load distribution across the chain cross-section.

These grips eliminate bending moments that could affect test results while providing secure specimen retention throughout the loading cycle.

Test Execution and Data Collection

The testing sequence began with specimen mounting in the chain-specific grips, ensuring proper alignment and secure retention without overtightening. Preloading to 890 N (30% of minimum tensile strength) followed ISO 606 requirements, allowing proper stress distribution and eliminating initial slack.

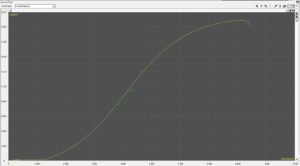

Test parameters programmed into the advanced material testing software specified a crosshead speed of 25.4 mm/min, maintaining slow force application as required by standards. Real-time monitoring captured force and extension data throughout the loading cycle, with particular attention to yield point identification and ultimate strength determination.