Weld Penetration Measurement System (TZM6565T-T3)

- Home

- IMAGE ANALYSIS SOFTWARE

- Weld Penetration Measurement System (TZM6565T-T3)

Weld Penetration Measurement System (TZM6565T-T3)

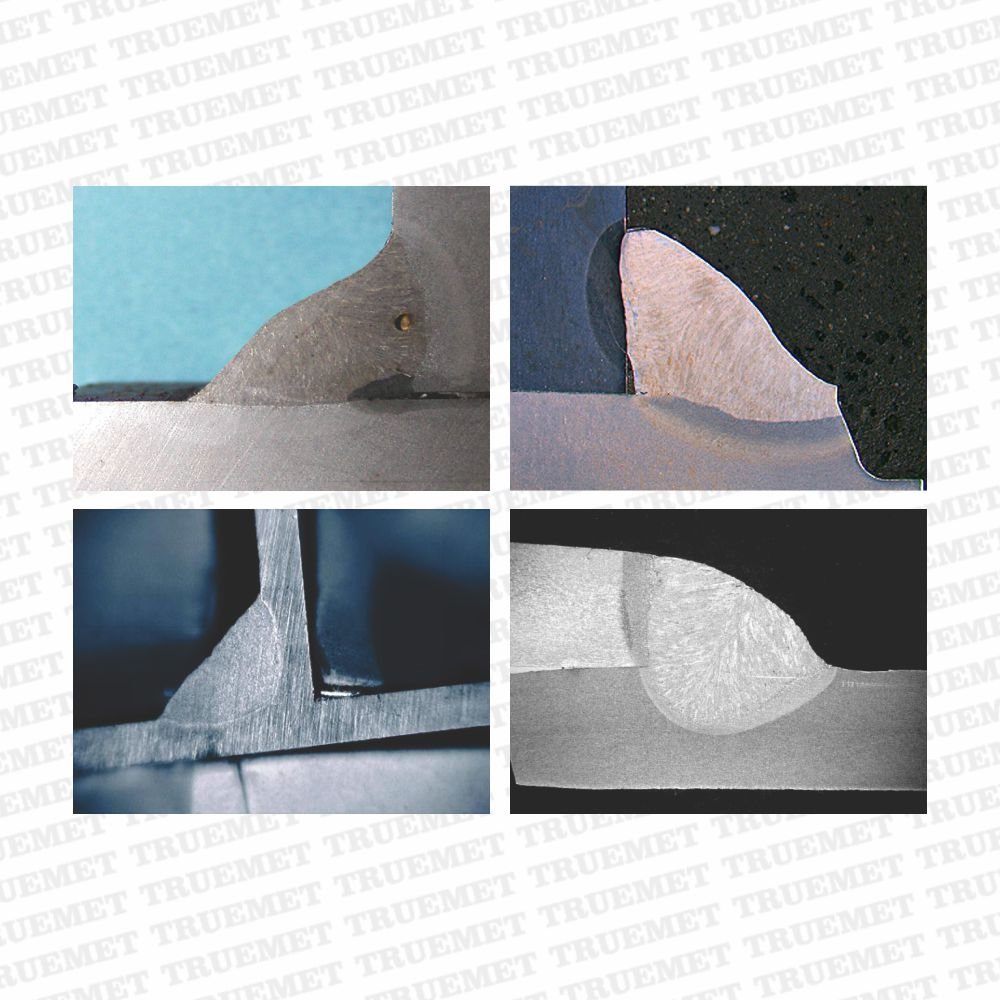

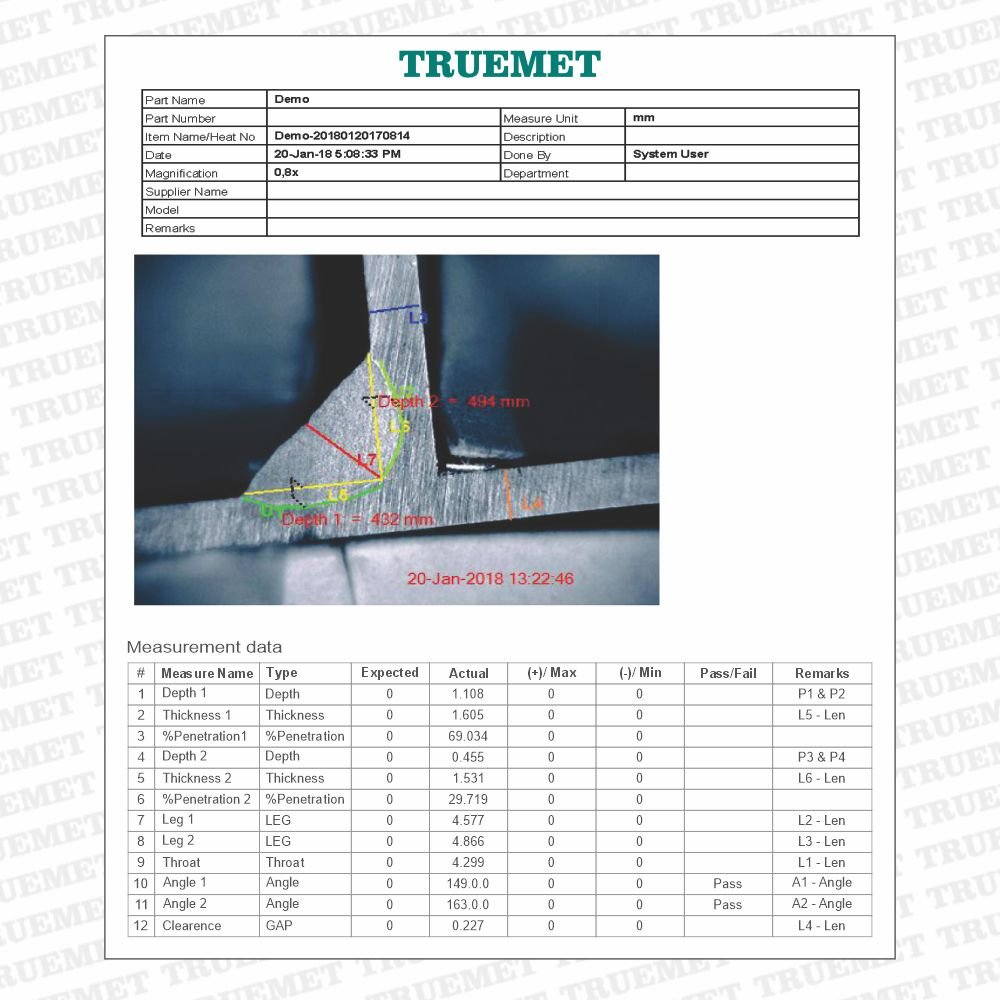

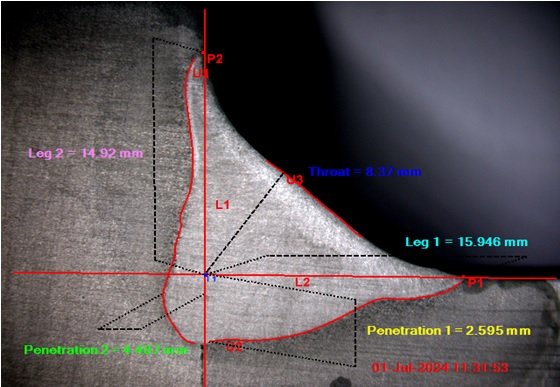

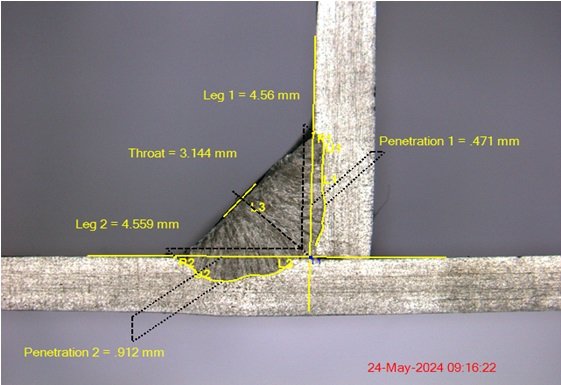

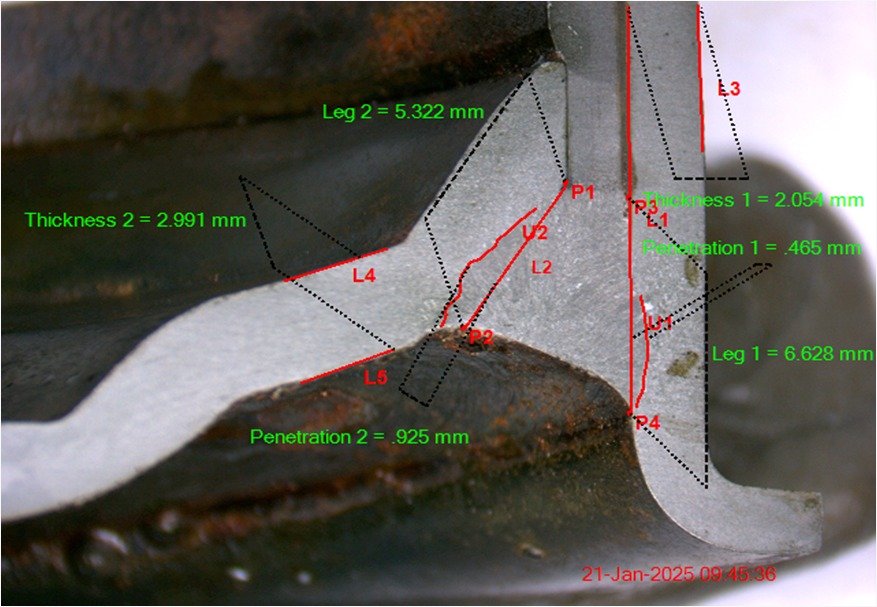

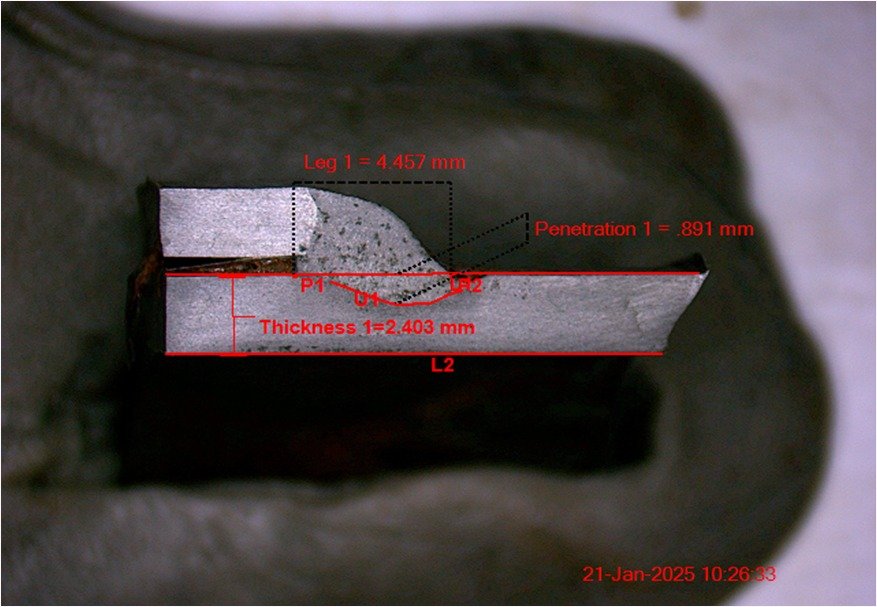

Weld Penetration Analysis Software Truemet’s advanced software enhances your welding analysis by providing precise measurements of weld penetration, fillet welds, throat, and leg lengths. Integrated with a Stereozoom Microscope, it ensures high accuracy and ease of use for detailed cross-sectional analysis. Explore our comprehensive solutions for accurate and efficient welding measurements.

Features:

- User-friendly Software

- Automatic Measurement

- Reports generated in PDF & EXCEL

- Component level and joint level reporting

- Menu driven measuring, ensures accuracy & repeatability.

- Draw and measure line, circle, angle, arc and curve can also extend lines.

- Create templates for each type of job.

Category: IMAGE ANALYSIS SOFTWARE

| MODEL | TZM6565T-T3 |

| Observation Head | Trinocular head, 45° tilt, 360° rotation, pupil distance 54—76mm; bilateral diopter adjustment ±5 diopters |

| Adjustable eyepiece | Standard configuration: WF10X22, High angle wide angle eyepiece, provide convenience for observers wearing glasses |

| Optional eyepiece | WF20X12mm |

| Objective | 0.65X—6.5X Zoom Range, objective magnification ratio 1:10, Ensure image alignment |

| Auxiliary Lens | 0.3X, 0.5X, 0.7X, 1X, 1.5X, 2X optional |

| Magnification | Standard 6.5X—65X, Optional and auxiliary lenses can be extended to 2X—260X, Continuous doubling |

| Working Distance | 110mm |

| Photographic eyepiece | 0.5XCTV |

| Base | T3 column type large plate base (Standard), Other base can be selected |

| Outward Size | 320mm(W) x 260mm(D) x 16mm(H) |

| Lighting Illumination | LED Ring light |

| Camera | 5 Mega pixel USB Camera |

| Resolution | 2592X1944 Effective Pixels |

| Color Format | Color |

| Sensor size | 1 / 2.5 inch |

| Lens mount | C mount |

| Data Interface | USB 2.0 |

| Power Supply | USB 2.0 |

| Optional Accessories | Computer (Min.) : Windows 10/11, Intel-i3 Processor, RAM- 4GB, SSD 512GB, UPS, Key Board, Mouse |

Frequently Asked Questions

1. Is the software easy to use?

- Yes, it features a user-friendly interface designed to make analysis simple and efficient for users of all levels.

2. Can I capture images directly within the software?

- Yes, you can capture images directly from the application for a seamless analysis experience.

Measurement Capabilities

3. What types of measurements can the software perform?

- The software supports a wide range of measurements, including:

- Point-to-point and linear measurements

- Radius and diameter for ellipses or rectangles

- Area and perimeter of ellipses

- Length of segmented lines

- Angle measurements

- Arc, ellipse, and circle measurements, including center point detection

4. Does the software detect key features automatically?

- Yes, it can automatically detect intersections and always calculates the shortest distance between points.

Drawing and Templates

5. What drawing tools are available in the software?

- The software includes tools to draw and measure lines, circles, angles, arcs, and curves, with the ability to extend lines for more precise analysis.

6. Can I create templates for repetitive jobs?

- Yes, you can create templates for each type of job to save time and ensure consistency.

7. Can the software handle large images or complex analysis?

- Yes, the image stitching feature allows you to combine multiple images for detailed and comprehensive analysis.

Reporting

9. In what formats can I generate reports?

- Reports can be generated in Excel, and PDF formats to accommodate various documentation needs.

10. How does the software ensure data validation?

- The software allows Pass/Fail analysis for data validation, ensuring precise and tailored analysis.